ABOUT LANTIAN

Jiangsu Lantian Heat Transfer Technology Co., Ltd. (hereinafter referred to as Lantian) is a professional industrial external cooling system thermal management solution provider controlled by "Gao Lan shares (stock code 300499). Lantian focuses on energy-saving technology innovation and product development and application in the field of heat and mass transfer. The company's technology comes from the team's profound theoretical knowledge and years of practical experience accumulation, as well as strong support from Xi'an Jiaotong University, Shanghai Polytechnic and well-known domestic experts. The company is equipped with advanced production equipment, high-level management team, and resolutely implement on-site 6S management to ensure high-performance, high-quality and fast delivery of manufactured products. Lantian can be tailored to a variety of complex cooling process requirements to develop a complete set of solutions.

Professional

Partners

Customer satisfaction

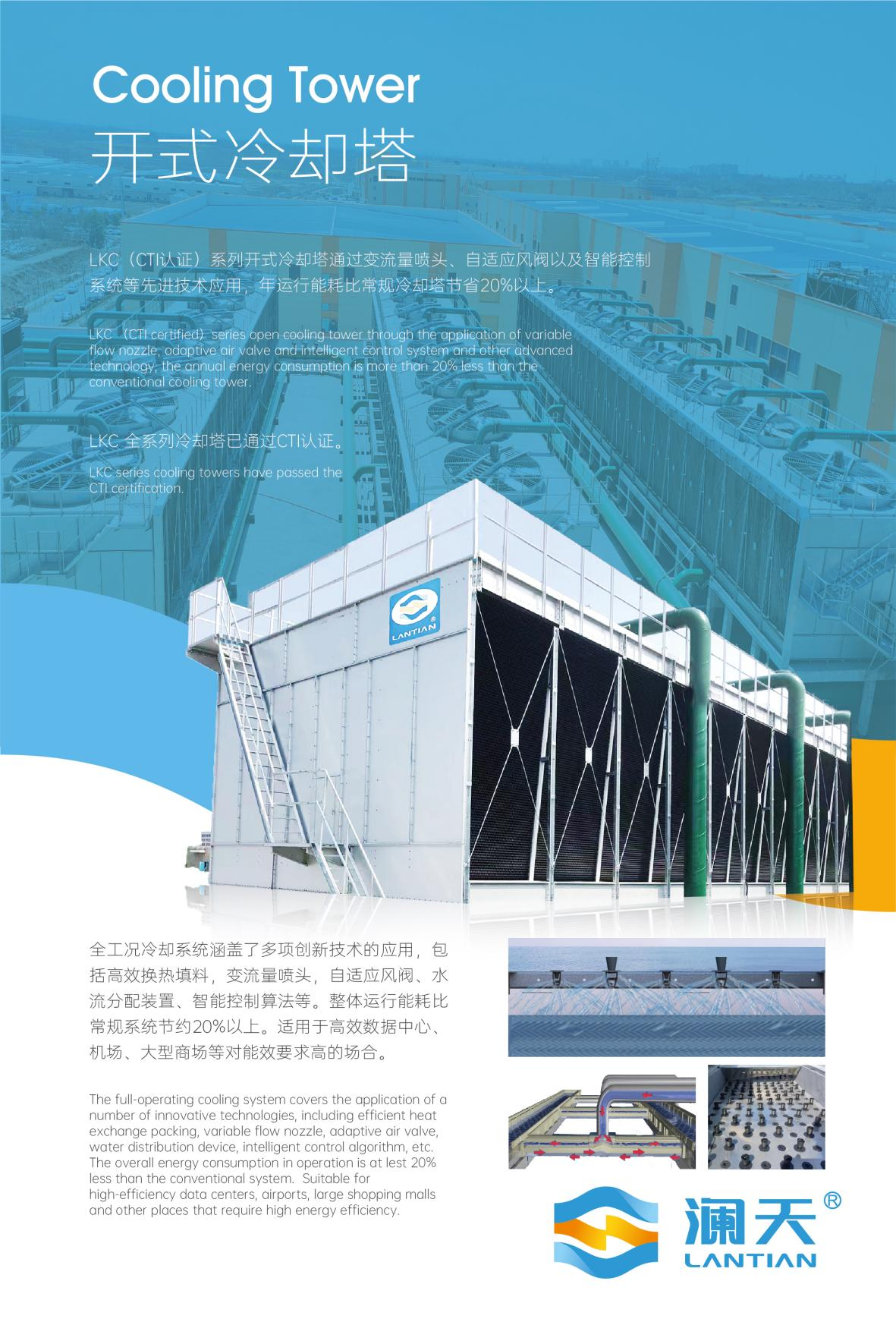

PRODUCTS

Professional provider of thermal management solutions for industrial external cooling systems

NEWS CENTER

Always share with you

2025-01-28

How to select a closed-circuit cooling tower

2025-01-16

Energy-efficient and environmentally friendly cooling technology

2024-12-20

Ensure efficient cooling and environmental protection