Product List

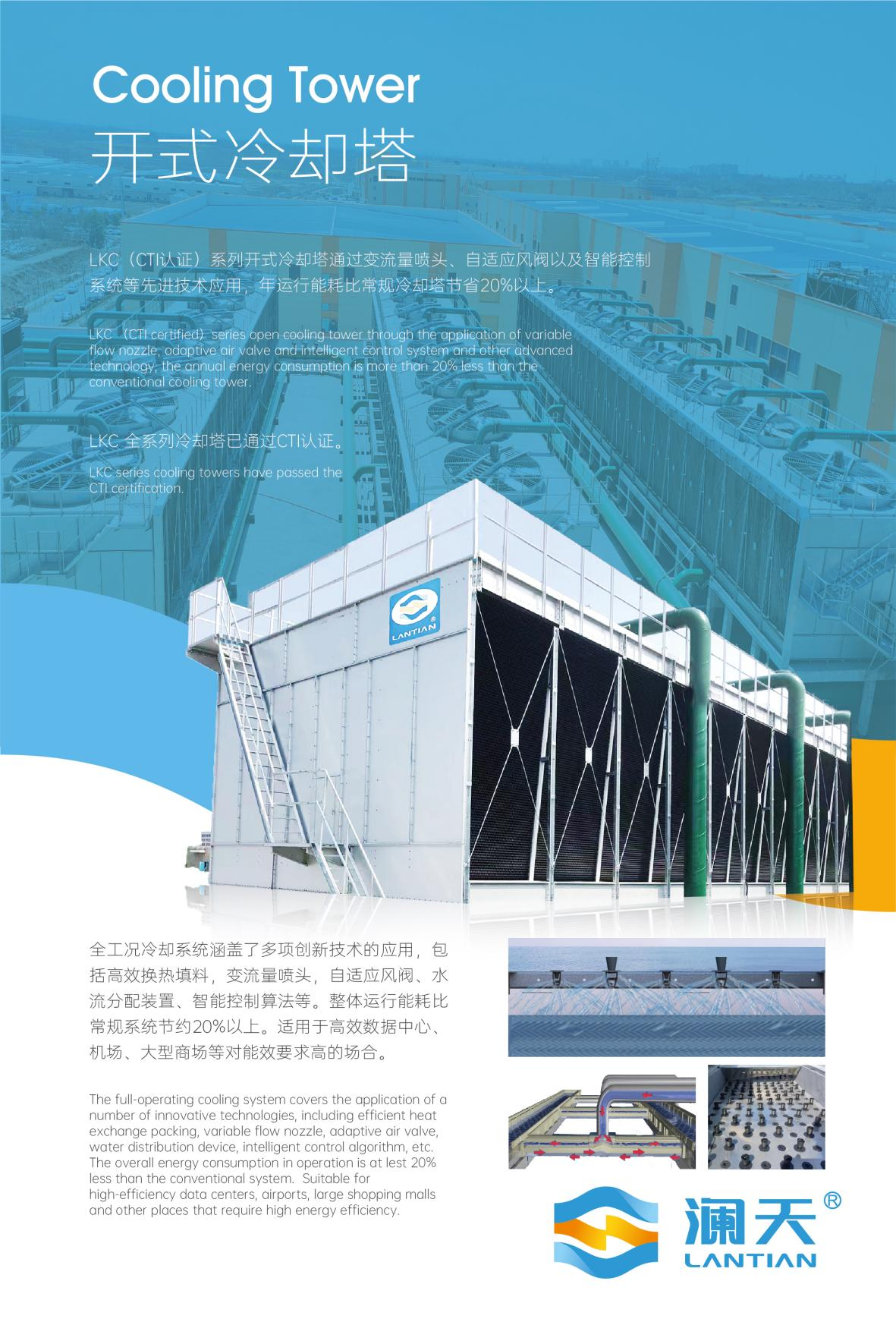

Closed Cooling Tower

- Commodity name: Closed Cooling Tower

- Description

-

A closed-circuit cooling tower is a device that uses the partial evaporation of the spray water outside the coil to absorb the heat from the high-temperature cooling water inside the coil, thus gradually cooling the cooling water in the pipe. Its main principle is that the spray water evaporates on the outer wall of the coil to cool the cooling water flowing inside the pipe, while simultaneously using a fan to remove the generated water vapor. A small portion of the spray water evaporates, while the rest is collected by the bottom collecting pan and recirculated. The cooling water with a higher temperature from the cooling system is pressurized and transported to the cooling coil of the closed-circuit cooling tower by a circulating water pump. On the other hand, a spray pump is used to draw water from the cooling tower sump into the spray pipe, which is then sprayed onto the outer surface of the cooling coil to vaporize and absorb the heat from the cooling water inside the coil, thereby reducing the temperature of the cooling water. The super strong wind power of the fan accessory equipment ensures that the spray water completely covers the surface of the coil, and at the same time creates negative pressure inside the box, reducing the evaporation temperature of the water, promoting water film evaporation, and greatly improving the heat exchange effect. Part of the spray water with increased temperature becomes gaseous, and a large amount of heat is carried away by the wind using the latent heat of vaporization of water. The water droplets in the hot air are intercepted by a highly efficient water separator, and the water that has finally absorbed the heat falls to the filling material below, is cooled by the air that flows through it, and then its temperature is reduced. Then, it flows into the collection pan, and is recirculated again by the spray water pump.

Meanwhile, a float valve is installed in the water pan to promptly replenish the moisture evaporated into the air.

Advantages: high heat exchange efficiency, good internal water quality, low resistance, low noise, long service life, water saving, and environmental protection.

Detailed Introduction of LTB\LTBN Series Products:

The equipment shell is made of high-quality magnesium aluminum zinc-plated steel, which is corrosion-resistant, scratch-resistant, dent-free, and features a rounded corner design to prevent scratches. Other configurations: imported galvanized steel G235, stainless steel 304/316L.

The water pump uses a low-noise, fully enclosed, splash-proof, and dust-proof outdoor motor. Equipped with a high-quality sealing ring, it is low-energy, high-performance, and long-lasting. Other configurations: protection level, explosion-proof motor, energy efficiency level, motor Brand.

The fan uses a direct-drive axial flow fan with an outdoor waterproof motor. It is low-noise, high-efficiency, maintenance-free bearing, and low-fault. Other configurations: protection level, explosion-proof/variable frequency motor, energy efficiency level, motor Brand.

The water separator is made of corrosion-resistant PVC material, effectively removing water droplets mixed in saturated moist air. It has a detachable design for easy maintenance, an integrated large filler, and a unique Lan Tian patented design with a water-collecting edge.

The spray system uses a detachable, high-flow, anti-clogging nozzle to ensure uniform spraying. The spray range is 70%-110%, improving the heat exchange efficiency.

The heat exchange steel pipes have undergone three air-tight pressure tests to strictly ensure reliable operation. The pipe ends are automatically welded for stable quality. Other configurations: 304, 316L, 2205, carbon steel pipe, titanium.

The intake louvers are made of high-quality galvanized iron aluminum zinc steel plate, which is corrosion-resistant and ensures uniform internal air speed, preventing water splashing and debris.

① Equipment shell

Made of high-quality magnesium aluminum zinc coated steel plate, corrosion-resistant and scratch resistant

Other configurations: Galvanized sheet G235, stainless steel 304/316L

② Dehydrator

Using corrosion-resistant PVC material, effectively removing water droplets mixed in saturated humid air; Detachable design facilitates later maintenance

③ Inspection gallery

The maintenance channel is convenient for subsequent maintenance

④ Water pump

Adopting a low-noise fully enclosed splash proof and dust-proof outdoor motor. Equipped with high-quality sealing rings

Low energy consumption, excellent performance, long service life

Other configurations: protection level, explosion-proof motor, energy efficiency level, motor brand

⑤ Fan

Directly connected axial flow fan, outdoor waterproof motor

Low noise, high efficiency, and few malfunctions

Other configurations: protection level, explosion-proof/variable frequency motor, energy efficiency level, motor brand

⑥ Spray system

Adopting detachable and high flow blocking nozzles to ensure uniform spraying and improve heat transfer efficiency

⑦ Condenser coil

Steel pipes undergo two airtight pressure tests to ensure reliable operation. Other configurations include 304, 316L, 2205, and carbon steel pipes

⑧ Packing material

Honeycomb filler, small wind resistance coefficient, anti-aging

Other configurations: PP/CPVC/PVC

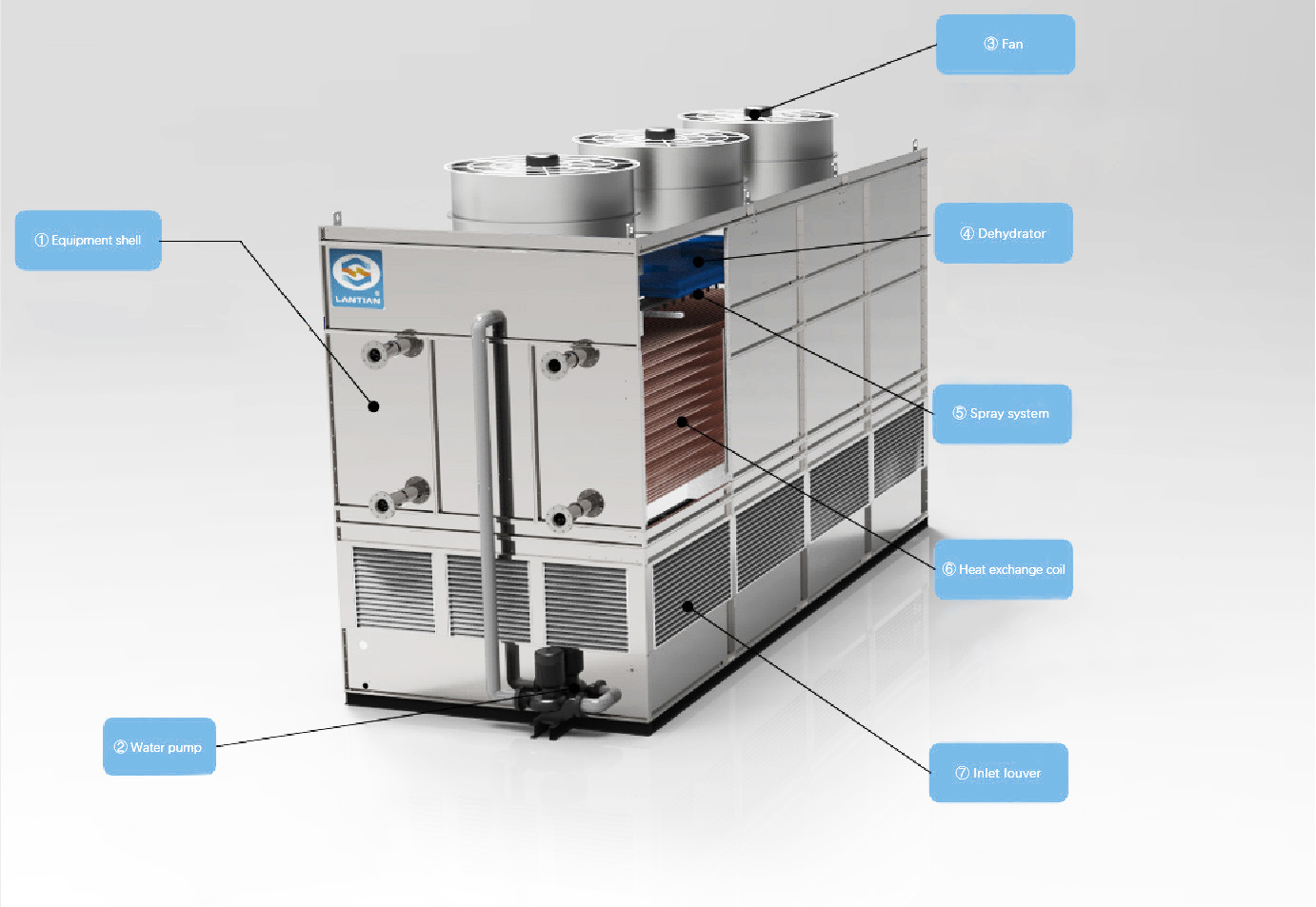

① Equipment shell

Adopting high-quality magnesium aluminum zinc coated steel plate, it is corrosion-resistant, scratch resistant, without indentation, and designed with rounded corners to prevent scratches

Other configurations: imported galvanized sheet G235, stainless steel 304/316L

② Water pump

Adopting a low-noise fully enclosed splash proof and dust-proof outdoor motor. Equipped with high-quality sealing rings

Low energy consumption, excellent performance, long service life

Other configurations: protection level, explosion-proof motor Energy efficiency rating, motor brand

③ Fan

Directly connected axial flow fan, outdoor waterproof motor

Low noise, high efficiency, maintenance free bearings, and few malfunctions

Other configurations: protection level, explosion-proof/variable frequency motor, energy efficiency level, motor brand

④ Dehydrator

Using corrosion-resistant PVC material, effectively removing water droplets mixed in saturated humid air; Detachable design for easy maintenance, integrated large filling material, unique LT patented design with water collection edge

⑤ Spray system

Adopting detachable, high flow blocking cold nozzles to ensure uniform spraying, with a spraying range of 70% to 6-110% to improve heat transfer efficiency

⑥ Heat exchange coil

The steel pipe has undergone 3 airtight pressure tests to strictly ensure reliable operation

The pipe head adopts automatic welding, with stable quality

Other configurations: 304, 316L, 2205, carbon steel pipe, titanium

⑦ Inlet louver

Made of high-quality magnesium aluminum zinc coated steel plate, corrosion-resistant

Uniform internal wind speed

Prevent splashing water and debris

Message

Please provide the following valid information and we will contact you as soon as possible.